For over 100 years MRS Training & Rescue has provided confined space rescue – and as accredited training providers today, we know how dangerous working in confined space can be. In this article, we explain what a confined space is, what the risks are – and the best safety practices to follow when it comes to gas detection.

What is an enclosed space?

According to the Oxford compact English dictionary, an enclosed space is defined as: “shut in on all sides” and “secluded from the outside world”. ‘Enclosed’ suggests that a person who is entering / working / existing in such an environment will have some restrictions.

What makes an enclosed space a confined space?

It’s important to note that an ‘enclosed space’ isn’t necessarily a ‘confined space’ and therefore doesn’t always have to be a cramped place. A confined space is any place, such as a tank, vat, chamber, pipe, flue, silo, pit, trench, well or other similar spaces in which, by virtue of its enclosed nature, there is a reasonably foreseeable specified risk.

Confined space hazards – what are the specified risks?

- Injury/death caused by fire or explosion

- Loss of consciousness a person at work caused by increased body temperature

- Loss of consciousness of an individual at work caused by harmful gas, vapour, fumes or lack of oxygen

- Drowning of any person from an increase in the level of liquid

- The asphyxiation of an employee at work caused by free flowing solid

It’s an employer’s duty to protect their employees and ensure their safety and health - this includes employers taking the time to understand and be aware of the hazards associated with confined spaces. Carrying out an assessment of the risks to health and safety ensures that employees won’t be exposed to a risk, and if there is a risk: is it to be made sure that it’s controlled at an acceptable level.

Gases within normal atmosphere

Risks of gas within a confined space - what should be included in hazard identification and assessment?

Regular assessments of the conditions within and around the confined space should take place, to identify what gases are or could be present. These could be obvious ones such as those produced from cutting or welding but could be less obvious such as cleaning with chemicals - this work doesn’t necessarily have to be carried out specifically in the confined area, it could be an associated area.

You should never forget to also assess which gases are potentially not present (i.e. oxygen).

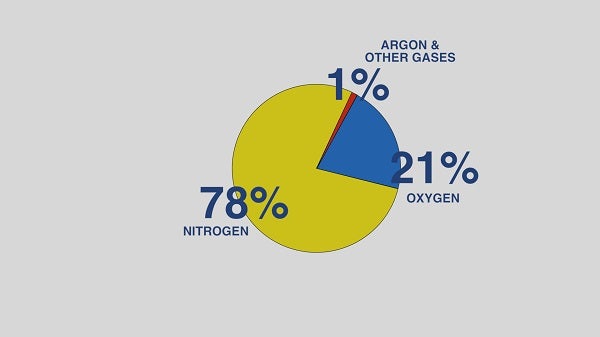

The three main constituent gases in the air are nitrogen, oxygen and argon.

Air is colourless, odourless and tasteless – it supports combustion and is essential for respiration. As air is a combination of gases, it is possible for separate gases to be isolated through specific processes.

Detecting gas, vapour or fume in a confined space

To keep employees as safe as possible, all confined space must be tested prior to persons entering. There are a few ways in which this can be achieved. By inserting tubing into the space and drawing out a sample through the tube to monitor, using a probe and drawing out a sample to insert into a detection device, or checking readings if fixed monitoring devices are present. In addition to this, an alternative way to detect gas, vapour or fumes in an enclosed space is by placing a detection device into the space itself and allowing it to record the conditions. An appropriate gas monitoring device will record peaks and troughs of gas readings obtained from the confined space: these should be available to those assessing the risks.

Testing for a gas as progress is made into a confiend space

Gas detection devices – a guide

Detection instruments can be supplied in various combinations of sensors. These vary from one sensor device for a specific gas to multi-sensor devices that often detect up to four gases. Things to consider when choosing a gas monitoring device include:

- What gases are you likely to encounter?

- Does the confined space have flammable gases (if so gas monitors may need to be ATEX approved).

- What materials are going to be in / introduced into the confined space? Silicas and other substances can ‘poison’ or ‘inhibit’ sensors, thus rendering gas monitors useless.

- How long are you going to be working in confined spaces – what is the battery life of the gas monitor?

- How accurately does the reading need to be? Chemical detector tubes are not highly accurate.Dusty environments may clog the sensors on the monitor – specific dust monitors are available

- Some gas monitors need to be ‘bump tested’ before use, so you will need to ensure you have the facilities to do this.

Ensure you select the correct monitor for your needs and work processes, to minimise the risk of damage to the monitor and thus danger to you and other workers.

There are many types of environmental / gas monitors to choose from - the two pictured here are the ones we at MRS Training & Rescue use.

Who should carry out gas detection testing?

The gas detection test needs to be carried out by a trained and competent individual who knows and thoroughly understands the features of the gases, fumes and vapours being distinguished.

The tester should also understand the relevant legal requirements and standards in association with carrying out gas detection.

Gas detection best practice

To keep the gas detection process as safe as possible, in addition to complying with associated legislations, it’s a good idea to follow best practice steps.

Points to consider when taking gas readings:

- Portable gas monitors are in widespread use when entering and working in confined spaces. Some gases can be lighter or heavier than air, meaning you’ll need to position the gas monitor into relevant areas.

- When taking readings with multi-gas monitors, it will take up to 30 seconds to get an accurate reading on some sensors due to the way that the sensor detects the gas.

- If an alarm goes off, all workers should immediately leave the area. If not exited in time, people can be exposed to a toxic, explosive, or an overall harmful environment.

- When testing for gas in a roof or cavity, it is important to note that the person taking the gas reading should not put their head above the gas monitor: this is due to the risk of a gas pocket being present, which can cause serious harm – including unconsciousness.

- If vehicles are ‘idling’ or if there are diesel generators in use, in the area you are gas monitoring in, there’s a risk of acquiring higher levels of carbon monoxide readings. To make the readings as accurate as possible – ask people to turn engines off and take the time to monitor the area carefully.

Gas detection process roundup

- What gases are likely to be encountered?

- Where are they expected to be found?

- Are there specific locations and times at which gas readings may need to be taken?

- Do readings need to be recorded and communicated to anyone?

You can never be too careful when taking precautions against the environmental conditions, so using your gas monitor thoroughly and methodically is extremely important and may just save your life.

Gas monitor in alarm condition