The Confined Space Regulations 1997 and the 2005 Work at Height Regulations both state that avoidance is always the priority wherever possible – avoiding entry into any confined space and avoiding working at height. However, removing the risk to humans of doing work in dangerous environments is not always possible and when avoidance cannot be achieved, there is a hierarchy of controls that should be followed:

- Risk assesses

- Control measures

- Safe system of work

- Emergency arrangements

One of the control measures that can now be used in such situations are internal inspection drones – and over recent years, they have been used successfully in many challenging industries such as chemicals, cement, power generation, warehouses, infrastructure and utilities, mining, oil and gas, amongst others.

All these industries undertake a range of maintenance operations that are in confined spaces or at height and need to be conducted in a safe manner – but also as economically as possible to reduce downtime.

Benefits of industrial drone inspections

The relatively new internal inspections drones now available on the market, allow technology to help avoid human entry into such spaces and initial inspections can be done in a fraction of the time.

So what are the key benefits of such drones?

- Improved safety – as already mentioned, sending in a drone to complete an initial inspection of difficult to access spaces, avoids the need for people to put themselves at risk. This not only relates to confined spaces but at height areas too – for example, using a drone to inspect high rise racking in warehouses, negates the need for people to work at height.

- Reduces downtime – a drone can fly into a space and provide live video and images immediately - meaning inspections reduce from days to just hours.

- Lower cost – using drones can maximise profitability compared to traditional means of inspections. They reduce time, manpower required and additional equipment as they can go anywhere where you would usually have to erect expensive scaffolding to access the space. Enabling companies to save money.

- Meaningful insights – drones can be used to inspect and survey assets, relaying the information in real time. The 4K optical camera can capture high resolution images and combined with the video, gives clear, factual and meaningful inspection feedback – nothing is open to interpretation or subject to anyone’s opinion.

- Quick response – by viewing in real time on the tablet exactly what the pilot is seeing, the customer can guide the pilot and advise on what to focus on during the flight and any specific photos to take.

What are the obstacles to using drones in industry?

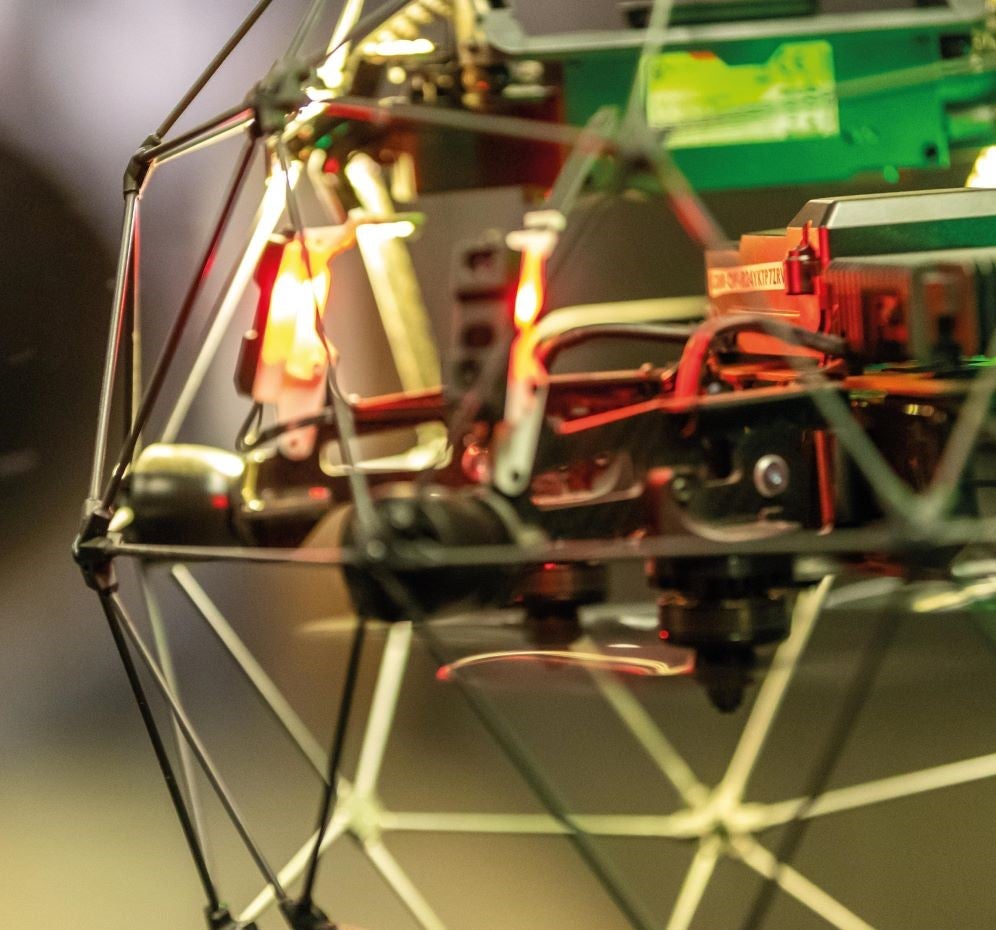

There is a natural mistrust when it comes to innovation – perhaps the idea and concept does not match up to reality? And drones can carry a stigma as they are thought of as toys – but these powerful internal confined space drones have many high spec features including an HD camera, heat senor, powerful lighting system – so certainly not playthings.

At MRS Training & Rescue, we have used internal inspection drones with a number of customers and been able to demonstrate the real value they deliver and the applications they can be used for.

When speaking with customers about the use of drones we have found:

- Some are unaware that drones could be used for inspections.

- Resistance – are we sure that the technology is mature enough to trust it.

- It is a departure from well known, used and trusted procedures of working – so change is required.

- Signal loss - Concerns over the drone flying into spaces not authorised. The drone flags if the signal is getting weak so the pilot can bring the drone back into a stronger signal area. If the signal is lost the drone just stops and does not fly off into the asset.

In summary

When it comes to conducting inspections at height or in dangerous areas, it can be extremely risky for humans. Fortunately, drone technology provides a safer and more efficient alternative. By using drones for inspections, the process becomes more streamlined, and the cost is significantly reduced.

Drone technology has a broad range of applications, and its potential is almost limitless. There is no doubt that the future of drone inspection technology looks bright, and we can only speculate on the advancements that will be made in the field. As we continue to witness the benefits of drone technology in various industries, it is clear that it will play an increasingly crucial role in inspections and other areas.

If you would like to learn more about the drone inspection services we offer, or the confined space and working at height consultancy we provide contact us.