What is wind energy?

Wind energy (or wind power) is the process of using wind to generate mechanical power or electricity. The most common way of generating wind energy is by using wind turbines. Wind turbines convert the kinetic energy of the spinning blades into electric energy by turning a drive shaft and gear box, which is connected to a generator. Electricity is then converted into higher voltages and fed into the national grid.

Wind energy in the UK

Wind power is the largest producer of renewable electricity in the UK. Onshore and offshore wind farms generate electricity by spinning the blades of wind turbines. The UK is windier than any European country and the windiest part of the UK is out at sea, so putting wind farms offshore makes total sense and why wind power is an important source of renewable energy.

How efficient is a wind turbine?

For a wind turbine to give significant energy the average wind speed per year must be at least 14 mph. Wind turbines are around 30-45% efficient at converting wind into energy.

There are three main factors that influence the power output from a wind turbine - wind speed, air density, and blade radius. Higher wind speeds generate more power because stronger winds allow the blades to rotate faster. Dense air exerts more pressure on the rotors, which results in higher power output. Larger blades allow the turbine to capture more of the kinetic energy of the wind by moving more air through the rotor.

In the UK, wind turbines are typically producing electricity 70-80% of the time, which makes them a reliable source of power throughout the year.

Wind Energy Careers

Demand for wind turbine technicians is predicted to grow over the next five years, due to the very rapid growth in onshore and offshore wind farms, as well as the need for older wind farms to be replaced or refurbished, as they come to the end of their working lives. So now is certainly a good time to consider working in this sector.

According to the Global Wind Workforce Outlook 2022 – 2026, a report by the Global Wind Organisation (GWO) and the Global Wind energy Council (GWEC), global onshore and offshore wind capacity is set to grow by 67% from 837GW in 2021 to 1,394GW in 2026, and a skilled workforce is needed to install and maintain this fleet safely and efficiently.

The GWO / GWEC report also indicates that more than 500,000 wind technicians will be needed by 2026 to meet the demands of the construction and maintenance of wind farms, if the world is to deliver the wind energy capacity required to meet net zero goals.

This represents a 33% rise in recruitment and thus training needs for wind turbine technicians.

Throughout the 20 years+ lifespan of a wind turbine, it will require maintenance to ensure it is running efficiently and to prolong its lifespan. This can include routine inspections to look at the condition of blades, underwater cables and gear boxes.

Is being a wind turbine technician a good career choice?

Wind turbine technicians maintain and repair wind turbines both on and offshore. Many wind turbines are in remote areas so before deciding if this job is for you, you must be comfortable with working in remote, hard to reach areas, and you should also be comfortable working at height and at sea (for offshore technicians).

You can discover more about a career as a wind turbine technician from RenewableUK.

What does a wind turbine technician do?

A wind turbine technician inspects, repairs and maintains wind turbines.

If wind turbines break, they are hard and expensive to fix. Lightning strikes often affect the integrity of a wind turbine and other malfunctions, or fires can occur in the gear boxes within the turbine itself.

So, maintenance is important to check issues with electrics, hydraulics and the mechanics of the turbine.

Before a wind turbine is installed, technicians also inspect all the component parts of a wind turbine before they are erected on site. It is much easier to repair any issues on a turbine when they are on the ground rather than when they are 100m in the air.

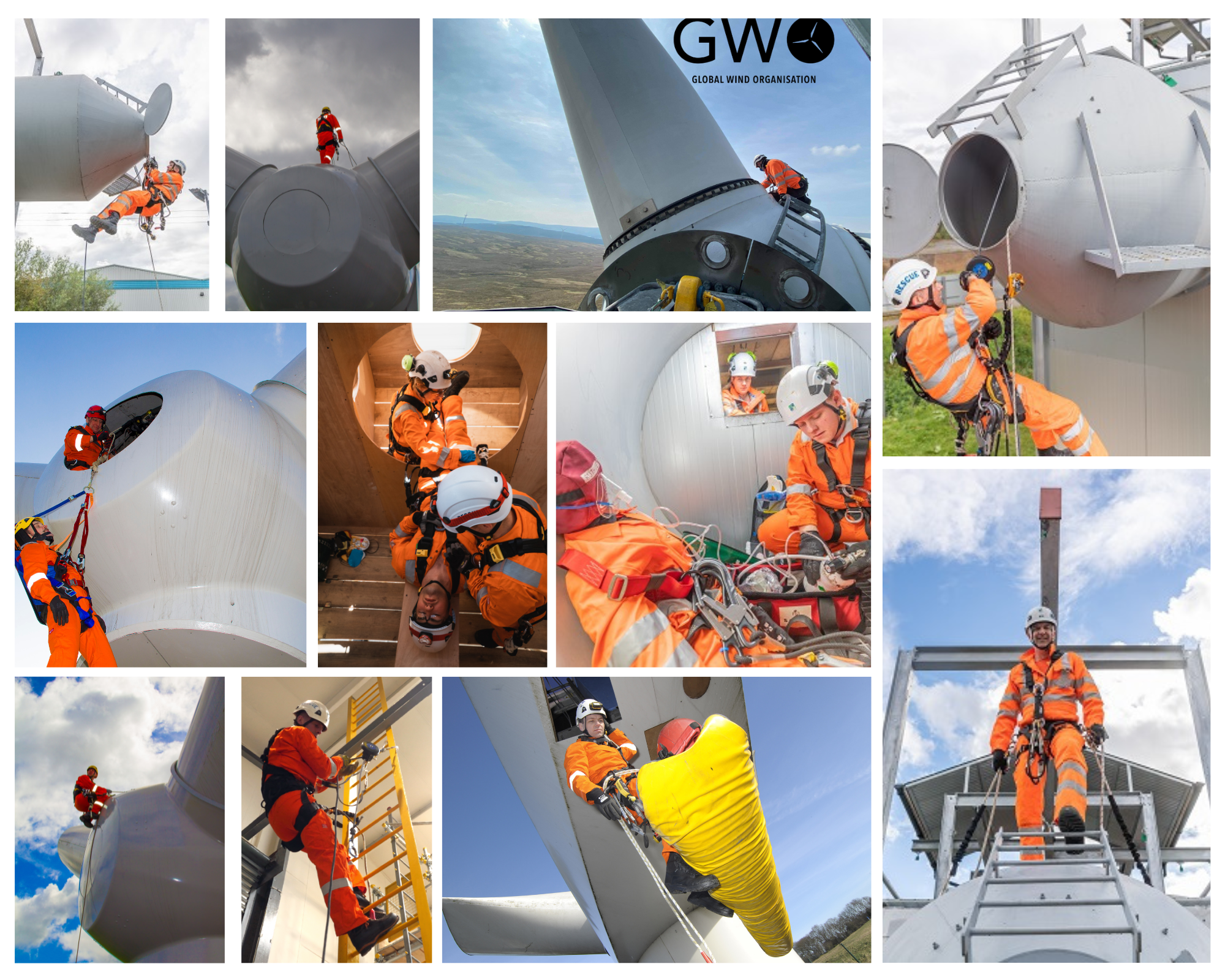

Technicians face different challenges every day and work can involve working in tight spaces. The nacelle is the heart of a wind turbine where the generator sits. Sometimes a technician’s work involves checking the motors inside the wind turbine. Work can also be required on the exterior of the turbine for which a technician will need to deploy rope access skills. If the blades need inspecting, technicians will need to use ropes to abseil down the blades on the outside to inspect and ensure no damage both on the surface of the blade and under the fibre glass surface of blades.

Why is being a wind turbine technician enjoyable?

Renewable energy is here to stay, and a growth area, so now is a great time to join the industry. And you are contributing to a better future for our planet.

If you enjoy work that is practical, outdoors, varied and has great job satisfaction, and you have a good standard of general fitness, then a wind turbine technician could be the career for you.

Although you must enjoy working in remote areas and not be afraid of heights – most wind turbine technicians work at around 100m above ground in the turbine’s rotor.

But the stunning views from the top of the turbine are amazing.

And the camaraderie of fellow technicians is especially important too – after all, they will be the ones to help you should a problem occur.

What qualifications are needed to become a wind turbine technician?

To work on a wind turbine, all wind technicians must hold a valid GWO Basic Safety Training Certificate. This comprises of four modules for onshore wind turbine work – Working at Height, First Aid, Fire Safety and Manual Handing – plus an additional fifth module for working offshore – Sea Survival.

This basic safety training will provide all wind technicians with the knowledge and skills to work safely on a wind turbine. Once passed, certification must be uploaded to the WINDA website and technicians must take refresher courses every 2 years before their current certificates expire, in order to remain competent and up to date in all aspects of basic safety.

In addition, many wind turbine companies now also require technicians to have passed an accredited medium risk confined space course, as by nature of the work conducted in a wind turbine by the technicians, they may become a confined space as defined by the 1997 Confined Space regulations.

Is being a wind turbine technician dangerous?

Wind technicians face hazards every time they work on a wind turbine. Working at height, overhead and rotating equipment, working in a confined spaces – e.g., hubs, nacelles, blades, towers etc - and exposure to weather which can be sometimes extreme. Also, if help is ever needed because of injury or illness, most wind turbines are hours away from emergency services.

However, with the right training and equipment, the risks are greatly reduced.

GWO Training at MRS Training and Rescue

We offer GWO accredited training at two of our training centres, in Fife in Scotland and Knottingley in West Yorkshire.

We will also soon be offering this training at our centres in Aberdeen and Rhondda in South Wales.

Facilities include purpose-built indoor training facilities to deliver an ultra-realistic training environment, a 17m tower for work at height training, and a decommissioned wind turbine at our Fife centre. In addition, we have an 8m scaffold access system designed to simulate industry scenarios for Working at Height, rescue, and training drills. Key features include ladders to perform ascending/descending exercises using twin hooks (for ladder rescue), trap doors, gates, hatches and guard rails, sloping and flat roofs, both with open edges. Additionally, freestanding towers enable training in suspension, a suspended rescue and a casualty stretcher rescue.

We are delighted to be able to support the wind industry and provide training that keeps delegates safe and capable of applying their learning in real life. Our instructors hold nationally recognised teaching and assessing qualifications and are experts in their subject matters. They are also operational rescuers working on turbines – so they have real-life stories, which brings the theory to life in the classroom. And our state-of-art facilities replicate the conditions that candidates experience working in their typical environment.

Our expertise in working at height and delivering GWO accredited courses has developed over many years, as have our facilities.

Our teams are passionate about what we do, and all work towards the same goal, unchanged since our inception in 1902, which is to keep people safe.