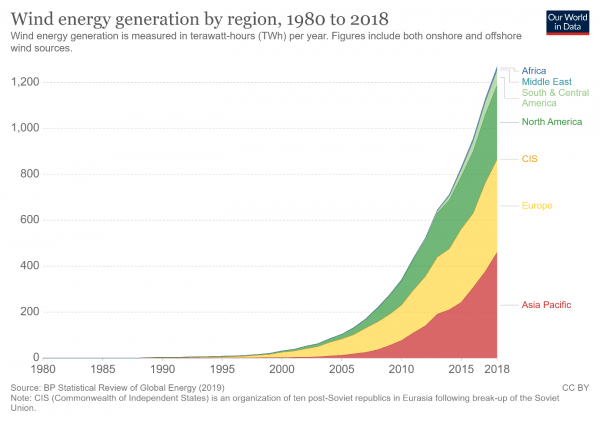

Wind power is nothing new – and today, wind energy is a growing source of renewable energy across the world. Wind turbines are now commonplace in the UK both onshore and offshore, and as technology evolves, they have become bigger, better and more efficient.

How long has wind been used to generate power?

It is thought that humans have used wind power for over two millennia. The first wind powered sailing boat is thought to be over 5,500 years old and windmills were thought to be used for irrigation in West Asia in 1700 BC.

The Dutch started using windmills (or molens) to pump water from wetlands in the 14th century, and by 1650 windmills were used to saw wood in shipyards.

The first wind turbine used to produce electricity was created by Prof James Blyth of Anderson College, Glasgow – and was 10 metres high. The cloth sailed wind turbine was installed in the garden of his holiday cottage in Kincardineshire and powered the lighting in the cottage. The wind turbine provided a surplus of electricity, which Blyth offered to power the local main street – but the offer was turned down as many still believed electricity was ‘the work of the devil’.

How much power is generated from wind in the UK?

In 2017, 15% of the UK’s electricity was generated from wind power. That is enough to power 12.7 million homes across the country. That figure is growing each year, with a further 629 onshore and 1,764 offshore wind turbine installations in the UK in 2019*.

How Do Wind Turbines Work?

Wind turbines produce electricity from wind. Sensors at the top of the turbine measure wind speed and direction to signal to the motor which way to point the nose (so it points towards the wind). The kinetic energy of the wind causes the blades to rotate, which spin a shaft connected to a generator that coverts the kinetic energy to electricity.

What are the Different Types of Wind Turbines?

Modern wind turbines fall into two main categories:

- Horizontal Axis Wind Turbines (HAWT)

Horizontal-axis wind turbines are those most common in the UK. They have three blades and operate "upwind," with the turbine pivoting at the top of the tower so the blades face into the wind.

- Vertical Axis Wind Turbines (VAWT)

There are several types of vertical-axis wind turbines (VAWT), including the Darrieus model, where the blades revolve around a vertical shaft.

VAWTs have some advantages. They have fewer components, can be grouped closer together as they can operate in turbulent winds and can catch the wind in any direction - as opposed to HAWT which needs to be pointed into the wind.

However, VAWT’s tend to be less reliable and less efficient so not as well suited to large scale energy production.

What is the difference between on-shore and off-shore wind turbines?

On-shore wind turbines are located on land and off-shore turbines are in bodies of water – often the sea. Off-shore wind speeds tend to be faster and more reliable than on-shore meaning more energy can be generated in a given time. However, off-shore wind farms can be expensive to build, especially if the water is over 200 feet deep.

Why are wind turbines white?

Wind turbines are almost entirely white in colour. This makes them neutral and non-intrusive to the landscape around them and they can blend with the sky and clouds. International aviation laws also require large structures are white so pilots can see them clearly in the air.

The white paint used on turbines also protects them from weather and prevents rust, as well as reflecting the sun away from the inner components

Why do wind turbines have 3 blades?

Traditional windmills have 4 blades so why do wind turbines tend to just have 3?

Every blade extracts kinetic energy from the wind and exerts torque. But the more blades a wind turbine has the more they experience drag and thus reduce the power extracted from the wind. Three blades ensure the angular momentum stays constant because when one blade is up, the other two are pointing at an angle. This allows the wind turbine blades to rotate smoothly and efficiently.

Wind Turbine Facts

- A wind turbine has 8,000 parts

- Good quality modern wind turbines last around 20 years

- Large wind turbines generate enough electricity in a year (about 12 megawatt-hours) to supply about 600 homes.

- The largest turbine in the world is GE’s Haliade-X, the industry’s first 12 MW turbine, that stands 260M high

- Large groups of wind turbines are called wind farms

- Industry experts predict that by 2050 one third of the world's electricity needs will be wind powered

- The blades on modern wind turbines can reach speeds at the tip of over 320 kph (200 mph).

- The largest onshore wind farm in the UK is in Whitelee, Scotland with 215 wind turbines and a capacity of 539MW

What does a Wind Turbine Technician do?

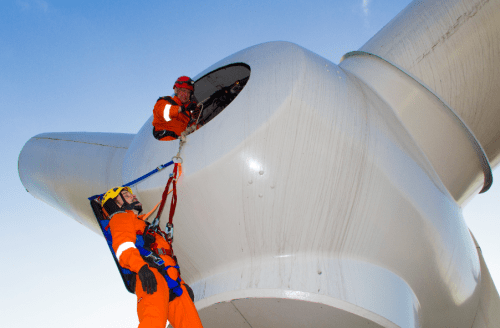

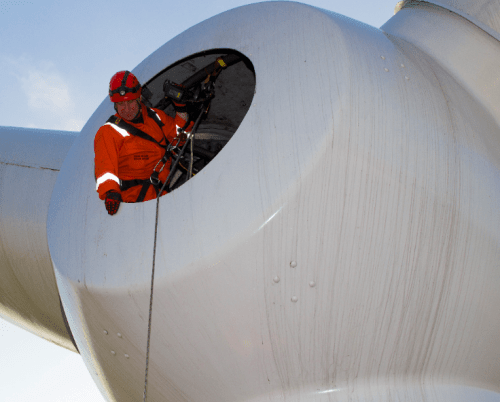

Although wind turbines have around 8,000 components, they are constructed of three main parts: a tower, blades, and a nacelle. The nacelle comprises of an outer case, generator, gearbox, and brakes, and most of the maintenance work on a wind turbine involves the nacelle.

When a problem is identified, wind turbine technicians use computers to diagnose the malfunction and then make the necessary repairs. They also do general routine maintenance 2-3 times a year to keep parts lubricated and in good working order.

Wind turbines are often located in remote areas, either onshore or offshore wind farms, with workers operating at considerable heights. They must climb ladders inside the tower – often 250 feet tall.

All workers must comply with the Working at Height Regulations 2005. These regulations stipulate that employers must ensure no person engages in any working at height activity unless he/she is competent to do so. Falls from height account for around 40 fatalities in the UK each year.

Furthermore, when maintaining mechanical systems, they work in the confined space of the nacelle.

What training do you need to be a Wind Turbine Technician?

When working on wind turbines you will be exposed to risk, so you must be properly trained to ensure you know how to work safely and are competent to mitigate those risks.

To become a wind turbine technician, you require some core skills and will need to complete the Basic Safety Training accredited by the GWO. This training covers First Aid, Manual Handling, Fire Safety and Working at Height and the entire course takes 5 days to complete. It needs to be renewed every 2 years.

Further training may be required depending on the role you are doing, and more advanced rescue and first aid training are available for anyone who may be working in very remote areas where they cannot rely on the emergency services for rescue or first aid.

What is the GWO?

The Global Wind Organisation (GWO) is a not-for-profit organisation created by wind turbine manufacturers and operators.

The GWO standardises training across the sector and those who are accredited, as we are, and can offer training which is recognised by those in the wind industry.

The body has developed common training standards across the wind industry which are accepted worldwide.

What is GWO Training?

MRS Training & Rescue are part of the GWO global network of certified training providers, delivering standards of training trusted worldwide anyone employed or seeking employment within the wind sector.

With turbine training facilities at our training centres in Knottingley and Fife, the training can replicate as far as possible ‘real-life’ field conditions.

Errol Parrish, Operations Manager at Fife said:

‘’We can offer realistic training in a safe environment, where the facilities consist of an actual wind turbine and a specially designed training tower. These provide our clients with the most realistic scenarios possible, enabling training to take place without the costs incurred from turbine shutdowns.”

“We are engaging with organisations and key stakeholders across the sector to highlight the courses available to the future generation of workers in this growing industry, to help to develop skills and create job opportunities. “

Our range of courses available to book online are:

- GWO Working at Height and Rescue (2-day course)

- GWO First Aid at Work (2-day course)

- GWO Manual Handling (half-day course)

- GWO Fire Awareness (half-day course)

These four courses combined provide the GWO Basic Safety Training package and run on concurrent days so all training can be completed in one week.

We also offer:

- GWO Working at Height and Rescue Refresher Course (1 day)

- GWO First Aid Refresher Course (1 day)

- GWO Enhanced First Aid (3-day course)

- GWO Enhanced First Aid Refresher Course (2 days)

- GWO Advanced Rescue Training (3 days)

We can also offer bespoke courses on request of the client, always with safety, quality and professionalism at the forefront of our minds.